Tiama intelligence systems

IT intelligence software gathering real-time data across the production line for analysis and management of the plant performances.

Display of the results on a single platform for a view at-a-glance of the plant productivity enabling to take correct, money saving decisions immediately, anywhere, anytime.

Tiama hot systems

Innovative technological bricks maximizing productivity

Modular process monitoring solutions for increased efficiency, optimized quality and minimized costs

A full range of sensors at the hot-end for a production process monitoring conducted through multiple parameters:

*gob’s weight, shape and temperature

*glass article’s position on the conveyor, dimensional measurements, infrared emissivity, defects detection…

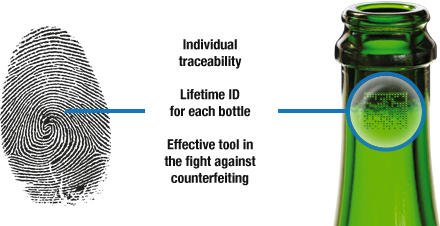

Tiama traceability Systems

Ability to provide a lifetime traceability for glass bottles

Unique container identification with a code engraved at the Hot-End offering bottle traceability throughout the glass plant process, throughout the bottling plant process and throughout the distribution channel.

Tiama inspection systems

Ability to provide a lifetime traceability for glass bottles

Unique container identification with a code engraved at the Hot-End offering bottle traceability throughout the glass plant process, throughout the bottling plant process and throughout the distribution channel.

Tiama services

A complete range of services for a global support of our customers. Simulators, online courses, training, audits, article tests…and many others to help our customers make sure that they make the most of their investment by allowing their people and production tools to perform at the best of their potential.

Long-term and strong support.

A real support of UPGRADE & RENOVATION of your machines.

You can access the online catalog here:

the spare-parts & the kits&upgrades

catalog.tiama.com

Contact Customer support:

Service@tiama.com

Tel: + 33 4 37 20 15 80

Tiama sampling solutions

Either at the Hot-End, Cold-End or Laboratory, Tiama develops new sampling solutions. One of them, the Tiama Xlab, is a revolutionary machine which uses Xray technology to create a 3D mapping of the container.

Tiama's products families at a glance