WEM: a Multi4 detection on the way to success

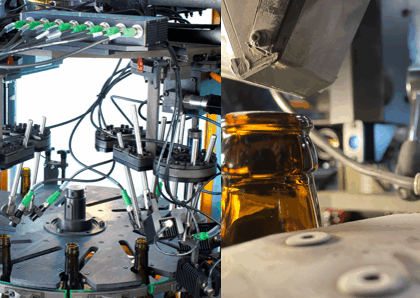

OPERATING PRINCIPLE

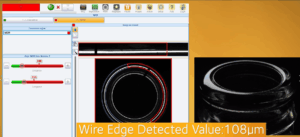

The WEM purpose is to measure the height of all glass protrusion in the inner part of the finish.

Thanks to dedicated mirrors inside a patented optical system, it is possible to combine several views of the finish to analyze and sort out container with defects, giving the exact value of the height of the defects for each container.

New HD cameras, designed and produced by Tiama, offer to this system twice as many pixels than the highest resolution used before for finish inspection. This change was a very important step for Tiama and it gives the ability to the system to measure the height of the protrusions in µm and to compare this precise measure to the acceptable threshold set by the customer.

Tiama also conceived a standardized optical system always placed 8mm above the finish and worked to make the mechanic part very easy to set up.

The inspection zone will be automatically positioned into the finish and, finally, the operator only has to configure two parameters to set the threshold for height and covered angle.

No need for long complex settings anymore.

[…]

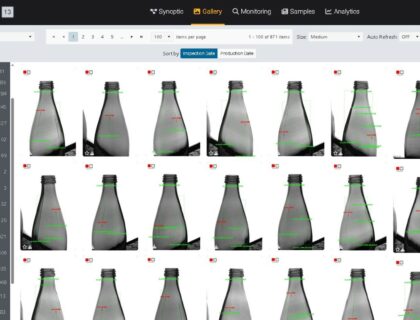

SMART FACTORY COMPLIANT

Tiama launched at Glasstec 2018 its Smart Factory Concept called YOUniverse, explaining how its five fields of expertise (Monitoring, Traceability, Inspection, Service and Intelligence) were all connected to move towards Smart Factory.

The WEM is fully in line with this development strategy. A reader displayed in the MULTI4 allows to associate the measures collected by the WEM inspection to a mold number or a Datamatrix code. These high value data can then be sent into Intelligent Supervision systems such as Tiama IQ scan. Before the association of these information, the customer could only detect the defects and sort out good bottles and bad bottles which meant a pack-to-melt decrease. Now, thanks to the data association and the precision of measures, the customer can be informed in real time of an increase in height of inner protrusion. This way he can anticipate production drifts at their early stage and act immediately on the concerned cavity even before a relevant defect occurs.

This is an extract from an article published in a magazine. To read the full article click here.