Performance meets Tiama precision in FKO and Saturn detection

Tiama’s FKO and Saturn detection systems represent a new era in container inspection, combining cutting-dge technology with unmatched ease of use. Together, they form a powerful duo, securing production, reducing waste, and elevating inspection standards across the glass industry.

FKO: A market-unique automatic inspection of flanges and knock-outs

FKO is Tiama’s latest innovation for detecting Flange and Knock-Out defects on thread and crown finishes, two of the most critical and harmful finish defects in glass containers. These defects can be as small as 60 microns, making them nearly impossible to detect with traditional inspection systems. Until now, no technology on the market could reliably reject them in line, on 100% of containers

FKO changes that. It uses a high-resolution camera and highly focused optics to inspect the ring edge during container rotation with a resolution of 50 pixels/mm.

It offers fast setup, no false rejects, and a quick return on investment as it can replace manual quality control and costly resorting costs.

FKO ensures top-tier quality and consumer safety.

If you want to know more about FKO click here

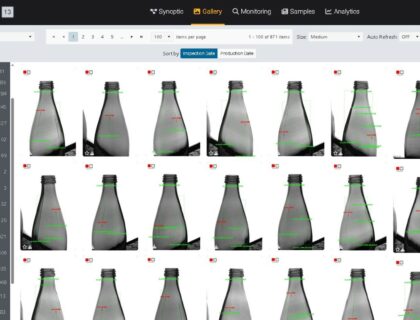

Simple setup, powerful results

The system is designed for simplicity and efficiency. Operators only need to configure two parameters, making setup quick and accessible without requiring specific expertise. The realistic image display from the camera helps define the inspection area effortlessly, while the correlation of counters and defects to mold numbers allows seamless integration with hot-end monitoring systems.

By identifying the latest critical defects and providing related images, FKO drastically reduces the risk of customer complaints.

Available on Tiama’s market-leading carrousel machines, FKO can be installed on both new and existing installations.

Saturn: Carrousel Check Inspection Reinvented

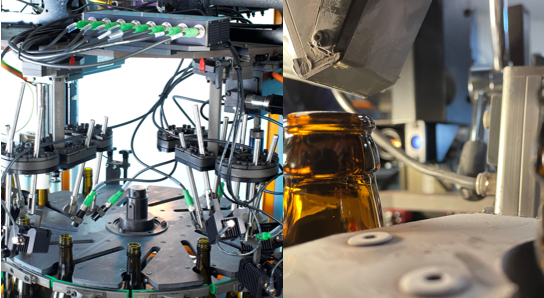

Saturn is Tiama’s new carrousel-based check detection solution, designed to replace manual inspection with a faster, more efficient, and more accurate system. With over 60

years of experience in check detection, Tiama has developed Saturn to meet the evolving needs of glassmakers.

If you want to know more about SATURN click here

Comprehensive Check Detection

Saturn enables inspection of all parts of the container, including the finish, shoulder, base, and body, with unmatched precision. Equipped with 6 to 11 wide-angle cameras, it captures up to 792 images per article to detect even the tiniest checks on bottles and jars. This ensures excellent coverage of all regions where defects are likely to appear, maintaining high production quality while significantly reducing false rejects.

A new product segmentation is also available to pair a Saturn 3 or 6-camera module with an already installed Atlas system for improved product performance.

Efficiency Through Simplicity

Setting up Saturn is remarkably simple. Once the cameras are oriented toward the article, operators only need to define detection thresholds and surfaces. This process simplification cuts job change time in half compared to standard systems. The system is integrated into Tiama’s latest user-friendly interface, making configuration intuitive and fast. The realistic image display further supports operators in positioning cameras and defining inspection zones with ease.

A Strategic Asset for Glassmakers

Saturn also delivers substantial operational benefits. By automating manual inspection tasks, it reduces labor costs and can lower resorting due to check defects by up to 90% compared to traditional technologies. Its compact and modular design allows for easy integration into existing machines or as a complement to an Atlas system for inspecting hard-to-reach areas.

This article was published in Glass Machinery World Plant and Accessories 05/2025. Read the edited version here.