Smarter quality control enabled by Tiama’s AI systems

Revolutionizing Vision Inspection: How AI is Transforming the Future of Quality Control

In the ever-evolving landscape of industrial automation, artificial intelligence (AI) has emerged as a game-changer, especially in the field of vision inspection machines. Once reliant on rigid rule-based algorithms, today’s inspection systems are being redefined by deep learning, real-time data processing, and intelligent defect classification. This revolution is not just about technology, it is about unlocking new levels of productivity, precision, and process insight.

From algorithms to intelligence: the shift to deep learning

Traditional vision machines operated on fixed parameters: operators manually defined defect zones, sensitivity thresholds, and acceptable tolerances. While effective, this approach was limited by its rigidity and dependence on human calibration. The development of deep learning has changed the game.

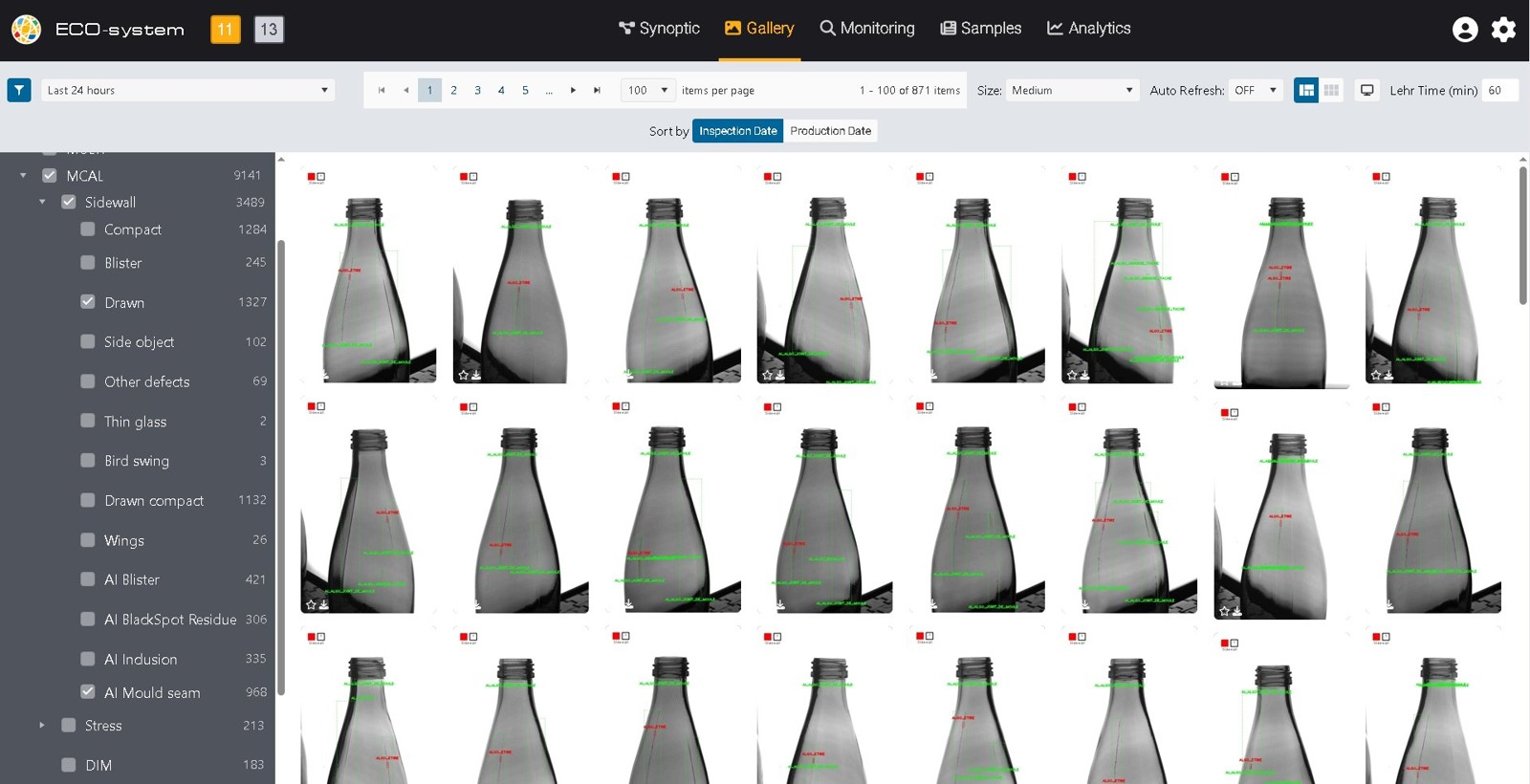

Deep learning models now recognize complex patterns, adapt to subtle variations, and continuously improve over time. It allows machines to detect defects with unprecedented accuracy, even in challenging areas like engravings or shadow zones.

Real-time inspection, redefined

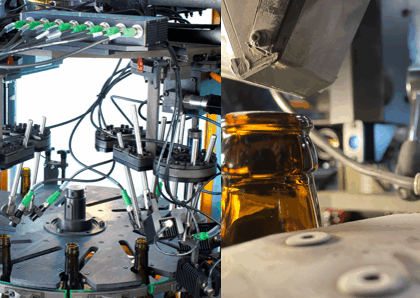

One of the most significant breakthroughs is the integration of AI directly into the inspection hardware. With the launch of the MCAL 4 AI, Tiama has embedded the computing power necessary to run neural networks in real time. Decisions are made instantly, enabling faster line speeds and immediate quality control interventions

Smarter machines, smarter processes

AI doesn’t just inspect, it understands. By assigning meaningful names to detected defects, AI systems provide actionable insights into the glassmaking process. This enables operators to trace root causes, adjust furnace or mold settings, and prevent recurring issues.

Moreover, AI’s ability to classify defects by type, mold location, and severity supports predictive maintenance and continuous improvement initiatives. It is a step toward the autonomous factory, where machines self-optimize and collaborate with operators in real time.

The benefits are tangible:

- Faster job changes: with a simplified setup, AI reduces the job change time by over 50%

- False reject reduction: By differentiating critical from non-critical defects (e.g., mold seams, small blisters), AI minimizes unnecessary rejects boosting productivity up to 1%.

- Improved detection: AI excels in identifying the exact type of defect, crucial for process improvement. Process operators can react faster by knowing which cavity and which type of defect they are producing

Scalable innovation: from retrofit to rollout

A key strength of Tiama’s AI strategy lies in its scalability and simplicity. All new MCAL and MULTI machines are AI-ready by design, while the entire installed base can be easily upgraded to benefit from the same cutting-edge capabilities, no full replacement needed.

Switch on AI is as simple as it sounds: just switch it on. This empowers customers to test, scale, and adopt AI effortlessly, unlocking innovation across all generations of machines.

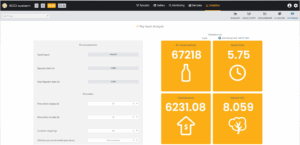

Measurable impact: from productivity to profitability

The results speak for themselves. In a furnace equipped with 10 AI-enabled sidewall machines, an additional 6,500,000 bottles are packed per year thanks to reduced false rejects and improved inspection accuracy. This translates into direct financial gains, reduced carbon footprint, and enhanced customer satisfaction.

AI also empowers operators. With intuitive interfaces and minimal setup requirements, even less experienced staff can achieve expert-level inspection performance. This democratization of technology is crucial in an industry facing skill shortages and high turnover.

Looking ahead: the road to autonomous inspection

AI is no longer an optional enhancement – it is a cornerstone of modern glass manufacturing. Tiama’s pioneering YOUniverse platform exemplifies this future, aggregating data from multiple inspection points for centralized process optimization. Cloudbased analytics provide remote monitoring, predictive insights and benchmarking capabilities. The journey toward autonomous inspection is well underway and Tiama is leading the charge – turning innovation into industrywide transformation.