DSM: a new feature for a 3D characterisation of the container finish surface

![]()

In the last 2 decades, Tiama was at the origin of some major breakthrough in the glass inspection industry. The NCT+ which was a non-contact thickness system, has revolutionized this type of control and helped glassmakers to decrease the weight of their articles. The NCG, launched more recently, can also be highlighted for ring and neck diameters. And finally Tiama launched in 2017 the WEM – Wire Edge Measurement – providing the possibility to measure the containers finish inner protrusions.

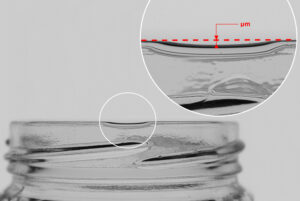

With the DSM, Dip and Saddle Measurement, Tiama is once again proving its inventiveness and proposing to its customers a major new step forward that will allow them to optimize the approach of this critical defect, especially in the production of jars.

[…]

Operating principle of the DSM

With a dedicated, patent pending light source, integrating optical mirrors produced by partners coming from Space industry, and highly defined cameras with five million pixels, the finish surface has never been more precisely characterized.

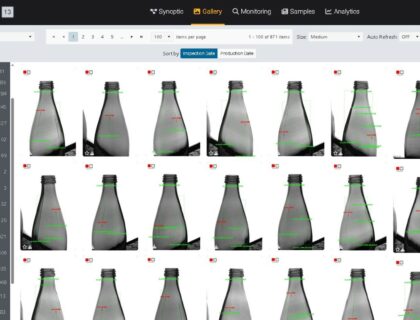

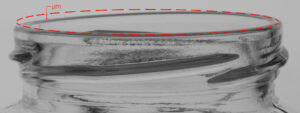

Moreover, where other solutions on the market are combining several 2D views with matrix cameras, not found to be precise enough to guarantee a good repeatability of measurements, Tiama system, with its high resolution images and optical principle, can give a very precise 3D mapping of the container ring surface that can be used to assess the quality of the container’s finish and establish the measurements of:

- Dip defects (lack of material of the finish surface) up to 150µm (± 15 µm)

- Saddle defects (Double and symmetrical distortion of the finish surface) up to 350µm (± 50 µm)

- Off level finish (Slope on the finish surface) up to 1mm (± 200 µm)

- Height Defects (± 200 µm)

Tiama device DSM, can be used to inspect all articles finish, and especially jars up to 110 mm diameters. It is effective on all glass colors and it can inspect up to 400 bottles per minute, as a new feature for MULTI4 machines or as a standalone solution.

This is an extract of an article published in a magazine. To read the entire article click here.