GMPA Article – Blank mold temperature regulation with Tiama HOT blank

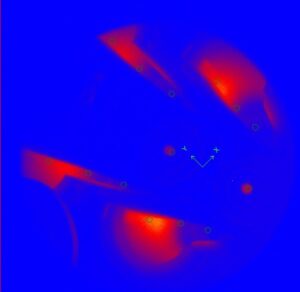

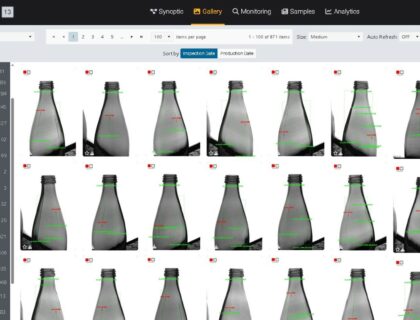

Offering automated optimization of both blank mold and plunger temperatures, TIAMA HOT blank ensures precise, repeatable measurements, temperature and ennhances efficiency. Introduced now by Tiama, it also improves process stability, reduces defects and aids informed decision-making for manufacturers – all thanks to its robust design and intuitive interface.

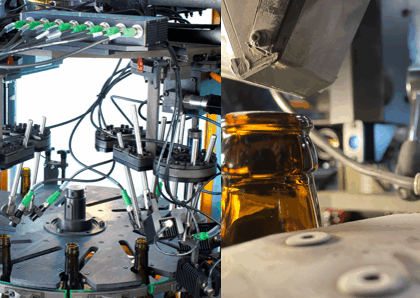

Launched at Glasstec 2024, Tiama HOT blank was designed to support glass manufacturers in production optimization.

Providing precise, reliable data and closed-loop to control the blank mold and plunger temperatures, it ensures enhanced efficiency and consistency. As part of the Tiama HOT systems range and aligned with the YOUniverse concept, this innovative solution provides precise and repeatable data on blank mold and plunger temperatures – enhancing both process stability and product quality.

Read the full article here published in Glass Machinery world plant and accessories