First practical results of process automation based on the Bottero/Tiama partnership

Few months ago, BOTTERO and TIAMA signed a partnership agreement introducing a joint co-operation between the two companies to identify the key parameters enabling to manage, to stabilize, control and optimize the production process and first practical results are already available to the market.

BOTTERO has developed a software tool to support setup and control of productions with multiple weight articles, the Multi Weight Manager (MWM): in principle, each section may produce a different weight, while the variable gob weight is achieved regulating the parameters of the servo feeder.

[…]

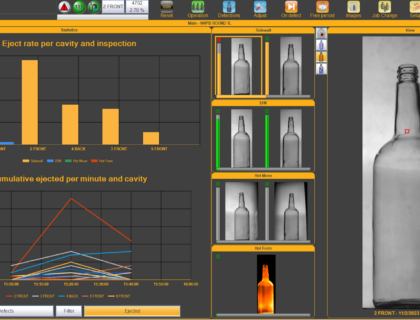

On its side, TIAMA has developed the Tiama HOT mass system. Camera based, this system calculates the speed and the volume of the gob while falling. The main objectives of the Tiama HOT mass are to regulate automatically the weight of the gob and to control its shape.

[…]

BOTTERO and TIAMA have worked together to integrate the Tiama HOT mass and the MWM in order to simplify the job change in case of multi-weight production.

When the user has given to the MWM the target weights per section, the MWM, as in the original version, applies the new settings, based on experience. Immediately, the Tiama HOT mass measures the volume / weight of every gob and transfers the results to the MWM. The MWM can then fine tune the settings based on the difference between the target weight and the one given by the Tiama HOT mass.

This is an extract from an article published in a magazine. You can read the entire article here