Maximising the output of your Hot End Process control

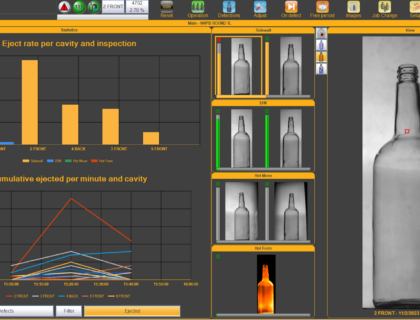

Tiama developed several sensors capable to characterize the process of glass forming. Those sensors gathered under the brand name of Tiama HOT systems are able to generate data needed to optimize the glass forming process whether it is at the gob cut with the Tiama HOT mass or on the hot end conveyor with the HOT system suite (I-Care, HOT Eye, HOT Form, HOT Move, and HOT Finish). For each of those systems, Standards of Practices have been developed in collaboration with our many customers. Each new system installed and each new customer organization have been an opportunity to strengthen and further elaborate our SOPs, feeding them with the interaction between our sensors and their data, and the optimal way to make use of these data in the forming process.

After several years of exploitation and more than 100 production teams working with Tiama SOPs, we are in a position to develop methods and guide any new comer in the hot end process control in the most efficient and timely manner. Tiama trainers, former glass plant experts, deliver the optimum approaches to value the customers’ assets.

This is an extract from a press release, if you want to read the entire article, click here