THE NCI/HCI [R]EVOLUTION

The quest for the perfect container for cold-end inspection

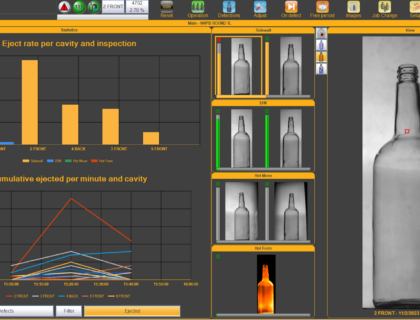

10 years after its very first release, time has come to reinvigorate this well-known inspection. But before getting into the substance of this new batch, it might be useful to recall the original aim of the NCI/HCI inspection. The NCI/HCI detection which stands for Neck or Heel Camera Inspection. Its purpose is to detect any possible defect located in those two specific areas. But imaging a defect and getting rid of the shadows generated by the glass itself is extremely strenuous on in-line machines. This is even harder when the diameter is small (in the neck of a container for instance) or when the article shape produces dark areas (push-ups). The objective of the NCI/HCI is to eliminate all these shadows by using line-scan cameras when rotating the container in a carousel machine.

The main hardware evolutions are the switch to home-made high-performance cameras, Tiama advanced electronics (Calia 3 CXP board integrated in the main frame computer) and a powerful and sharp LED lighting. All these hardware enhancements make it possible for the software to integrate all the latest developments of Tiama machines. Therefore, the NCI/HCI inspection is based on the proven MCAL4 software, benefiting of all its experience and powerful algorithms to search and identify the tiniest deficiency.

This text is an extract from an article published in a specialised magazine. To read the entier article, click here.