Tiama HOT mass 2: Maintaining the highest standards of gob control

To ensure efficient production, consistent product quality, and environmental responsibility in the glass packaging industry, it is essential to focus on various aspects of the manufacturing process. Given that 80% of defects originate from gobs, according to glass manufacturers, monitoring them is a key step in improving process control. This level

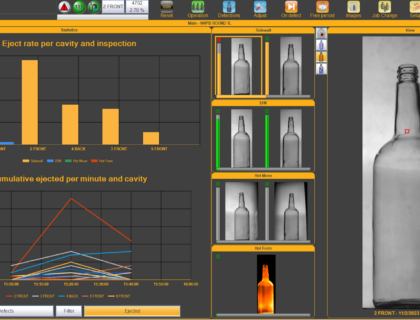

of diligent surveillance also plays a central role in optimising glassmaking operations, reducing waste and maintaining brands’ high standards. The Tiama HOT mass 2 is the latest generation of Tiama’s hot end product range dedicated to gob monitoring. The inspection and quality control specialist’s new sensor was launched at glasstec 2022 to replace the original Tiama HOT mass and GIA [Gob Image Analyser] system.

This is an abstract of an article published in Glass Worldwide. You can read the full article here on their website or download the PDF here.