Tiama Traceability to make every container individual and unique

The industrial world of glass is quickly evolving just like the needs of glassmakers, bottlers and final consumers. Today, Traceability counts as one of the growing challenges and the requested level of quality keeps increasing.

Counterfeiting, distribution channels control, returnable loops, marketing needs and consumer safety are topics pushing the beverage industry to rethink its strategy of the global process, from the glassmaker to the consumer.

In order to satisfy this need, the glass industry brought 3 answers:

- The Cold-end marking is a limited solution to add a serial number on the container but it can damage the glass and affect the pressure resistance of the container. Plus, it has no value for glassmakers

- The Hot-end marking with alphanumeric digits improves the quality and process management, but this kind of code is not readable automatically and does not answer to bottler request anymore.

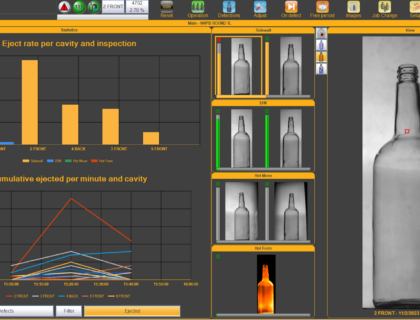

- 10 years ago, Tiama decided to develop datamatrix encoding at the hot-end. This code presents many advantages as it is unique, secure, redundant and resistant on every container and stays all along the product life cycle, from the gob to the final consumer.

The individual container traceability will drastically shake up the way of managing the container and its content. It makes possible to trace the origin of a bottle at any time and gets its information such as the exact time of production at the hot-end, the cavity number, the line number and even more.

This is an extract from an article published in a magazine. To read the entire article click here.